INTEGRAL COLOUR

Tech Data Sheet

Product Description

INTEGRAL COLOURS are pure synthetic iron oxide pigments that contain no fillers,

adulterants or admixtures that will affect the characteristics or performance of the concrete mix design.

Warranty/Disclaimer

Warranty/Disclaimer

Because the conditions of use and application of our products are beyond control, Stoney

Creek Ready Mix makes no warranty of fitness or merchantability for any particular purpose

and expressly disclaims liability for incidental or consequential damages whether based on

negligence or warranty. Buyer’s sole remedy shall be the refund of Colour purchase price

from point or purchase.

Colour selections are approximate as closely as possible appearance of Colour when used on

horizontal troweled and/or imprinted concrete. Variations can be expected due to job

conditions, cement finishing techniques, use of sealers and slight raw material Colour drifts.

Due to the natural source materials in cement and handcrafted nature of imprinted concrete,

variations are acceptable and desirable.

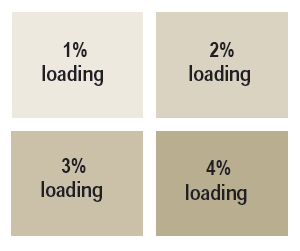

Loadings in four-color groupings are

represented as follows:

Directions

1) Mix Design

• Integral Colours are quality controlled and consistent. Several factors can affect

the final appearance of concrete. Follow all directions carefully to ensure

consistent batches.

• Concrete should be poured at no more than a 4” slump. Adding water to loads

will result in faded colour. Do not use calcium chloride. If an accelerator is

required, use a non chloride additive. Recommended air entrainment for

regions subject to freeze/thaw cycles is 5-8%.

2) Finishing

• Do not add water to concrete load as setting in place. Begin finishing after

bleed water has evaporated. Finishing techniques should be consistent. Do not

add water as a finishing aid. Any washed tools should be dried before applied

to concrete surface.

3) Curing

• Curing using burlap, plastic, etc. will cause discolouration.

COLOURS FOR CONCRETE